Nitroethane is a versatile chemical compound used in various industrial applications, from organic synthesis to specialized coatings. However, handling it requires a thorough understanding of its properties, hazards, and safety precautions. This guide covers the best practices for managing nitroethane safely, including proper storage, handling techniques, and protective measures. Learn how to minimize risks, comply with safety regulations, and maximize efficiency when working with this compound.

Key Applications of Nitroethane in Industry and Research

Nitroethane is widely utilized across various industries due to its unique chemical properties, making it a valuable compound in both industrial and scientific applications. In the field of organic synthesis, nitroethane serves as an important intermediate in the production of pharmaceuticals, agrochemicals, and specialized solvents. Its reactivity allows for the formation of complex molecules, which are essential in drug development and fine chemical manufacturing.

In coatings and adhesives, nitroethane acts as a solvent and viscosity controller, contributing to the formulation of paints, varnishes, and industrial adhesives that require precise consistency. Additionally, its presence in the electronics industry supports the cleaning and degreasing of precision components, ensuring reliability and performance in sensitive electronic systems.

The compound is also studied in academic and industrial laboratories for its role in developing novel materials and conducting fundamental reaction mechanism research. Researchers explore its potential in advanced chemical synthesis, investigating its interactions and transformations in various controlled reactions.

Given its widespread use, proper handling and storage of nitroethane are essential to prevent degradation and ensure workplace safety. Appropriate ventilation, controlled temperature conditions, and adherence to safety protocols are critical when working with this compound. Understanding its applications and properties allows industries and researchers to maximize its potential while prioritizing health and environmental considerations.

How to Safely Store Nitroethane: A Step-by-Step Guide

Proper storage and transportation of nitroethane require adherence to specific safety measures to ensure its stability and prevent hazards. Storage conditions should include a cool, dry, and well-ventilated area, away from direct sunlight, heat sources, and ignition points. Containers must be tightly sealed and made of compatible materials, such as stainless steel or polyethylene, to prevent leaks or chemical reactions. Labeling should be clear and compliant with regulatory guidelines to identify the substance and associated risks.

During transportation, nitroethane must be handled by trained personnel who follow industry-standard procedures. Use approved hazardous material containers that provide adequate shielding from physical damage. Ensure that transport vehicles are equipped with necessary safety equipment, including spill containment kits and fire extinguishers. Route planning should consider regulations for hazardous materials, avoiding densely populated areas when possible. It’s crucial to plan transport routes in accordance with regulations concerning hazardous materials. Additionally, ensure the transport vehicles comply with standards for transporting hazardous substances. This includes having the appropriate certifications and safety equipment.

Regular inspections of storage areas and transport containers help identify potential issues before they develop into serious hazards. Maintaining a comprehensive safety protocol and ensuring compliance with local and international regulations reduce the risks associated with handling nitroethane, protecting both personnel and the environment. Always ensure compliance with local and international regulations during transport and storage, as emphasized by organizations like OSHA (Occupational Safety and Health Administration) in the US and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) in Europe.

My Personal Experience with Nitroethane Storage

In my experience, properly storing nitroethane is paramount. I once witnessed a minor incident where improper storage led to a dangerous situation. The key is to ensure the storage area is consistently cool and well-ventilated. Here’s a quick checklist I use:

- Temperature control: Keep the storage area below the recommended temperature to prevent any unwanted reactions. For nitroethane, maintaining a temperature below 25°C (77°F) is generally recommended to ensure stability.

- Ventilation: Ensure adequate airflow to dissipate any potential fumes. Aim for a ventilation system that provides at least six air changes per hour to prevent the buildup of hazardous vapors.

- Container integrity: Regularly inspect containers for any signs of leaks or damage. Check for corrosion, bulging, or any other signs of wear that could compromise the container’s integrity.

- Segregation: Store nitroethane away from incompatible materials and ignition sources. Incompatible materials include strong oxidizers, strong acids, and strong bases, as these can react violently with nitroethane.

Best Practices for Handling Nitroethane: A Practical Guide

Working with nitroethane requires a meticulous approach to ensure safety and efficiency. Having worked with it for several years, I’ve developed a few best practices that I swear by.

Personal Protective Equipment (PPE) is Non-Negotiable

Always wear appropriate PPE, including chemical-resistant gloves, safety goggles, and a lab coat. Specific glove materials like nitrile or neoprene offer good protection against nitroethane. Safety goggles should be ANSI Z87.1 certified to ensure adequate eye protection. In situations where vapor concentration might be high, use a respirator. Use a NIOSH-approved respirator with an organic vapor cartridge to protect against inhalation of nitroethane vapors. Always perform a fit test to ensure the respirator provides a proper seal.

Ventilation is Your Best Friend

Work in a well-ventilated area or under a fume hood to minimize exposure to nitroethane vapors. A fume hood should have a face velocity of at least 100 feet per minute to effectively capture and remove vapors. This simple step can significantly reduce the risk of inhalation.

Avoid Open Flames and Sparks

Nitroethane is flammable. Keep it away from open flames, sparks, and other ignition sources. This includes ensuring that electrical equipment is properly grounded. Use only non-sparking tools and equipment in areas where nitroethane is handled or stored to prevent accidental ignition.

Spill Response Protocol

Have a spill response plan in place. This should include having absorbent materials readily available and knowing the proper disposal procedures. In case of a spill, contain the area, neutralize the spill with an appropriate absorbent, and dispose of it according to local regulations. Use spill kits containing materials like vermiculite or activated carbon to absorb the spill. Dispose of the used absorbent material as hazardous waste, following EPA guidelines.

Regular Training and Awareness

Ensure that all personnel handling nitroethane are properly trained on its hazards and safe handling procedures. Regular refresher courses can help reinforce these practices. Training should cover topics such as chemical hazards, proper PPE usage, spill response, and emergency procedures. Keep records of all training sessions to demonstrate compliance with safety regulations.

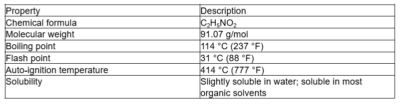

Understanding Nitroethane’s Properties: A Quick Reference

To safely use nitroethane, it’s essential to understand its key properties. Here’s a quick reference table:

Complying with Safety Regulations: What You Need to Know

For more detailed information and to purchase nitroethane, you can visit Eulab Industry.

Learn how to handle nitroethane safely, explore its key properties, and discover best practices for its various applications: https://eulabindustry.com/gb/strona-glowna/132-nitroethane-5907745979767.html.