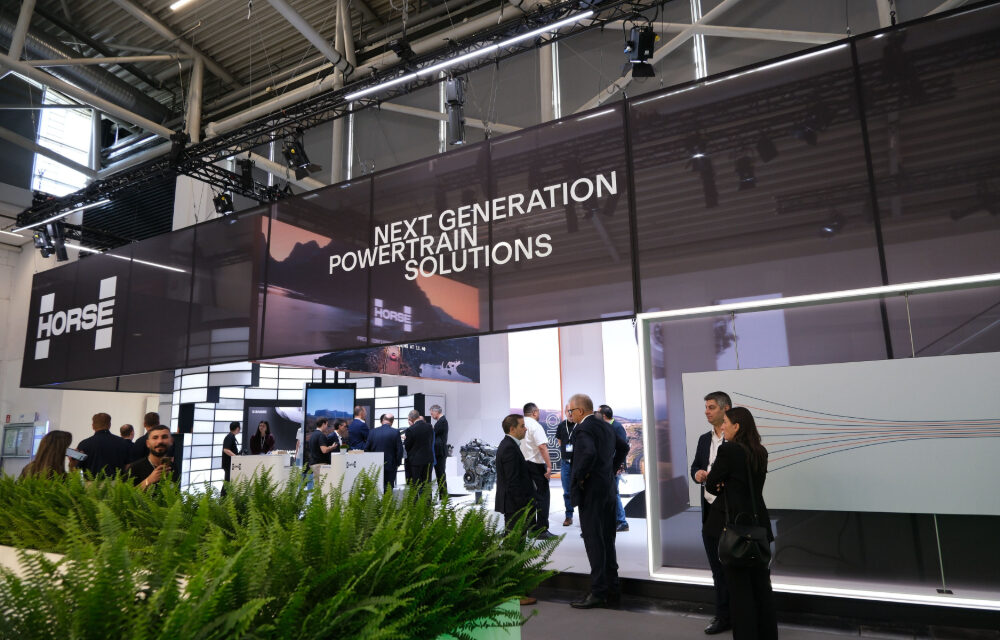

- Company reveals all-new Horse C15 compact range extender powertrains, its “all-in-one” Future Hybrid System to hybridize BEVs, and its 4DHT120 hybrid transmission

- IAA Summit 2025 features full line-up of engines, transmissions, and power systems at Hall A2, Booth B40, leveraging new fuels and materials

- A global leader in hybrid and combustion powertrain solutions, Horse Powertrain operates 17 plants and five R&D centers around the world

Munich, Germany (8 September 2025) – Horse Powertrain, a leader in innovative and low-emission powertrain solutions, has revealed its range of next-generation integrated powertrain systems at IAA Summit 2025.

Hero Systems

Horse C15

Following its global announcement last week, IAA Summit marks the first public debut of Horse Powertrain’s groundbreaking Horse C15 compact range extender systems: a new product line of integrated engines and generators in a briefcase-shaped package.

Measuring just 480x490x250mm, the first Horse C15 unit is a 1.5-litre, four-cylinder engine with a generator, exhaust, and cooling package. For B-and C-segment vehicles, a naturally aspirated variant will be able to achieve a maximum output of 70kW. For larger D-segment vehicles and small LCVs, a turbocharger boosts output up to 120kW.

Critically, because of its size and shape, this new family of compact range extenders can be installed horizontally or vertically, unlocking exceptional flexibility in allowing OEMs to convert their BEV platforms into range-extended electric vehicles (REEVs). Horse C15 can be powered by a range of fuels, including gasoline, ethanol and methanol flex fuels, and synthetic fuels.

Future Hybrid System

First shown earlier this year at Auto Shanghai, Future Hybrid System is a revolutionary “all-in-one” hybrid powertrain that combines an engine, transmission, motor, and power electronics into a single system. It replaces the front electric drive unit of BEV, offering an affordable and effective way to convert BEVs into hybrid EVs (HEVs), plug-in hybrid EVs (PHEVs), and range-extended EVs (REEVs), with minimal modifications to the platform.

At IAA Summit, Horse Powertrain detailed the first two variants of Future Hybrid System:

- Performance: a 740mm-wide variant which employs two motors in a P1 + P3 configuration (one at the engine output shaft, and another at the transmission output shaft).

- Ultra-Compact: a 650mm-wide variant which uses a motor in a P2 configuration (between the engine and transmission).

Both variants use a 1.5-liter, four-cylinder engine and dedicated hybrid transmission. They also contain the full suite of power electronics required for hybrid powertrains and can also seamlessly integrate with systems like a DC/DC converter, on-board charger, and an 800V charging booster to maximize performance at low voltages.

Both variants allow a BEV to be converted into an all-wheel-drive REEV in conjunction with a P4 motor (located near the rear axle), with no modifications required to the front compartment’s structure. Further, Future Hybrid System’s Performance variant can independently propel a vehicle on its own, providing a cost-effective FWD-only hybrid solution.

Horse 4DHT120

Iterating on current technology, Horse 4DHT120 is a “5-in-1” unit that combines an eMotor, Hybrid Starter Generator, Power Electronics Box, DC/DC converter, and transmission. It can be paired with a hybrid-friendly engine of any fuel type, allowing OEMs to easily hybridize combustion vehicles and diversify their model line-ups.

Horse 4DHT120’s motor is capable of 80kW of continuous power and 140kW peak, with maximum torque of 300Nm and maximum speed of 16,500rpm.

The unit’s power electronics box is directly built into the transmission’s housing. This unlocks a dramatic improvement in packaging efficiency, while also enabling a more efficient internal layout that minimizes friction. The result is that Horse 4DHT120 delivers the critical driving “feel” of an EV, while also providing outstanding fuel efficiency for both city and highway driving.

Engines & Transmissions

Horse M20 Hydrogen

The Horse M20 Hydrogen system creates an opportunity for OEMs to adapt existing vehicle architectures to be powered by low-emission alternative fuels. Derived from an existing Horse Powertrain 2.0-liter, four-cylinder turbo diesel engine, the Horse M20 Hydrogen provides up to 90kW of power and 300Nm of torque. Along with meeting upcoming Euro7 standards around nitrogen oxide emissions, the engine produces less than one gram of CO2 emitted per kilometer driven.

Key to the Horse M20 Hydrogen is a groundbreaking direct injection and ignition system, featuring new intake ports, piston crowns, and combustion chambers to reduce the injection pressure of hydrogen fuel, improving engine efficiency. The result is a 10:1 compression ratio that enables hydrogen fuel utilization rates of 94.3%, comparable to the efficiency of hydrogen fuel cell technology – all without requiring for rare minerals.

Horse B15 Engine & Horse 3DHT160 Transmission

Developed for use in HEVs, PHEVs, and REEVs, the 1.5-liter, four-cylinder Horse BH15 gasoline engine leverages the battery of its vehicle to make significant efficiency gains over previous generations of hybrid engines. Along with using battery charge to power the vehicle’s electric motor, Horse BH15 uses electricity from the battery to power a high-energy ignition system, a water pump, an electrically assisted turbocharger, and an electronic exhaust gas recovery system.

In addition to these innovations, Horse B15 also integrates intelligent control technologies that work together to regulate the engine in real-time. Altogether, this means it achieves an ultra-high thermal efficiency of 41.7%, with a maximum power output of 120kW and peak torque of 255Nm.

This is designed to be paired with a high-performance hybrid transmission, Horse 3DHT160. This gearbox is designed to be used in both series and parallel hybrid working modes, allowing it to feature in HEVs, PHEVs, and REEVs.

Horse 3DHT160 uses a P1 + P3 motor configuration, with one motor positioned where the transmission meets the engine output shaft and another at the transmission’s output shaft. This configuration allows the 3DHT 160 to support the engine, significantly improving vehicle responsiveness, efficiency, and acceleration. This is all achieved at a low mass of just 138kg.

Components & Subsystems

Turbulent Jet Ignition System

Developed in collaboration with Aramco, the Turbulent Jet Ignition (TJI) system is a replacement for traditional engine spark plugs. This system uses high-energy turbulent jets emanating from a pre-chamber to ignite the air-fuel mixture in the engine’s main chamber, dramatically improving combustion efficiency – meaning significant improvements in fuel economy and emissions performance.

Horse Powertrain’s TJI solution stands to be a major driver in hybrid powertrain efficiency gains in the coming years. Laboratory tests adapting Horse Powertrain’s existing 1.8-litre, four-cylinder “HR18” engine to use TJI have achieved a 5% reduction in the engine’s WLTP emissions – a step-change in helping global OEMs deliver a new generation of low-emission vehicles. Start of production is planned for 2029.

GaN High Efficiency Generator

Designed for use in range-extended electric vehicles (REEVs), the Gallium Nitride (GaN) High Efficiency Generator is designed to convert mechanical energy from an engine crankshaft into electrical energy.

This new generator is one of the first in automotive to leverage a GaN power module. Chips using GaN enjoy faster switching speeds and superior thermal performance compared to traditional silicon chips, while also being smaller and lighter. This enables the generator to achieve significant performance gains, while also unlocking new integration opportunities through the module’s improved size and heat dissipation profile.

As a result, the GaN High Efficiency Generator can operate in temperatures as low as -40°C, and as high as 110°C. Capable of outputting 50kW at 4500rpm, it is also capable of top speeds of 5500rpm – all with an ultra-high efficiency of 95%. And by leveraging the size efficiencies unlocked by the GaN power module, the generator’s axial length is 20% lower than silicon-based generator solutions for REEVs.

Amorphous Motor

Developed for use in a dedicated hybrid transmission, the new Amorphous Motor is designed to leverage ultra-lightweight and highly conductive amorphous steel. By using sheets of amorphous steel that are just 0.025mm in width, the Amorphous Motor reduces iron losses by over 50% – dramatically increasing the amount of power available for output.

As a result, the Amorphous Motor can achieve levels of efficiency without precedent in automotive: 98.2%. At the same time, the motor can output maximum power of 140kW and produce peak torque of 360Nm.